Unleashing the Power of Capacitor Technologies: From Electrolytic to Ceramic and Tantalum

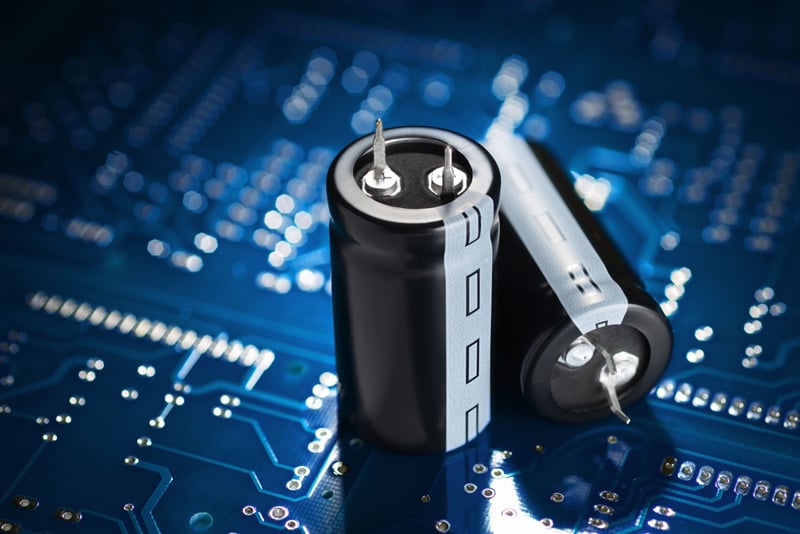

Capacitor Electronic Parts unveiled

In the realm of electronics, capacitors are the unsung heroes that fuel innovation and power a vast array of devices we rely on daily. These small yet mighty components come in various forms, each tailored to specific applications and performance requirements.

In this editorial piece, componentscse.com , an electronic component equivalent finder, embarked on a captivating journey to explore the diverse world of capacitor technologies, from the classic Electrolytic to the versatile Ceramic and the tantalizing Tantalum. Join us as we unravel their unique characteristics and the pivotal roles they play in modern electronic designs.

Electrolytic Capacitors: A Classic Choice for Energy Storage

Electrolytic capacitors, the workhorses of energy storage, excel in applications requiring high capacitance values and stable performance. Their construction involves a conductive electrolyte that allows for significant charge storage. Widely used in power supplies and audio systems, these capacitors provide high capacitance in a compact form, ensuring efficient energy transfer and signal filtering.

Ceramic Capacitors: Versatility in a Tiny Package

When it comes to versatility and affordability, ceramic capacitors take the spotlight. With a wide range of capacitance values and voltage ratings, these compact components find their way into almost every electronic device imaginable. Their stability over a broad temperature range makes them ideal for signal coupling, decoupling, and voltage regulation in everything from smartphones to spacecraft.

Tantalum Capacitors: High Performance in a Small Form

Tantalum capacitors boast remarkable characteristics that make them the preferred choice for demanding applications. With high volumetric efficiency and low equivalent series resistance (ESR), they excel in compact and high-performance electronics. Aerospace, medical devices, and telecommunications equipment often rely on tantalum capacitor parts for their exceptional reliability and long lifespan.

Aluminum Electrolytic Capacitors: Balancing Performance and Cost

A cousin of the electrolytic capacitor family, aluminum electrolytic capacitors strike a balance between performance and cost-effectiveness. They find extensive use in power supplies, audio amplifiers, and industrial equipment. Their ability to withstand high ripple currents and voltages makes them essential in applications that require reliable energy storage and filtering.

Film Capacitors: Delivering Precision and Stability

Film capacitors offer precision and stability in a diverse range of applications. With plastic, metalized, and polyester variants, these capacitors provide high insulation resistance, making them ideal for use in electric circuits, motor drives, and consumer electronics. They are prized for their low losses, high reliability, and ability to handle both high and low temperatures.

Conclusion: Capacitor Technologies – Fueling Electronic Advancements

As we dive into the realm of capacitor technologies, we uncover a rich tapestry of components, each tailored to meet the specific needs of modern electronic designs. From the classic electrolytic’s energy storage prowess to the versatility of ceramic and the high-performance tantalum capacitors, these tiny components play a monumental role in shaping the world of electronics.

In the pursuit of innovation, we find ourselves in awe of these unassuming yet powerful devices. Capacitors continue to evolve, supporting the development of cutting-edge technologies in the realms of renewable energy, telecommunications, automotive, and beyond.

Next time you hold an electronic device in your hands, take a moment to appreciate the remarkable capabilities of capacitors, the unsung heroes silently empowering our connected and electrified world.